Workflow management strategic management sales and marketing supervisory control production data collection short time scheduling.

Rfid technology for shop floor production controlling.

Planning and scheduling decisions are more practically and precisely made and executed.

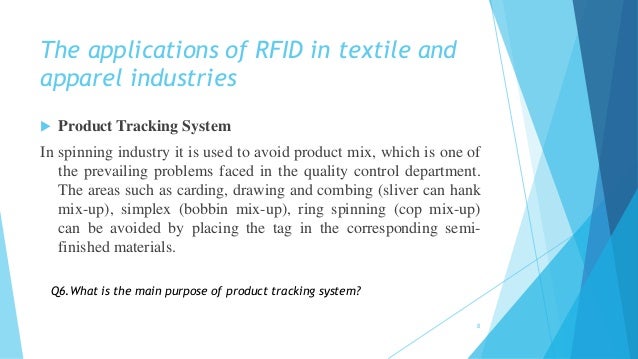

Rfid production tracking system is an old technology still it has the potential for garment factories for automizing production tracking and reporting.

These systems use rfid radio frequency identification or barcode technology for real time information capturing.

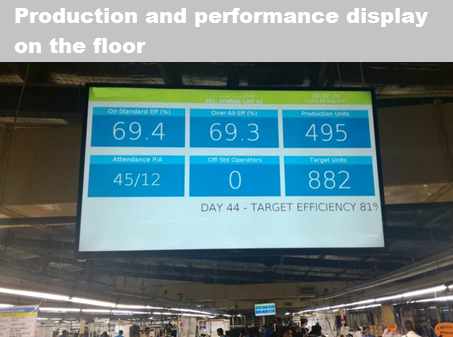

Information tracked via rfid readers terminals from the shop floor is processed through software and provides various real time reports that help managing production.

Getting production counting from each workstation operation wise as well as operator wise production data knowing how operators spend the given time when they are on the shop floor.

G pro shopfloor data tracking sdt is a real time shop floor data collection and feedback system designed specifically to meet the production control and management needs of the apparel industry.

Disturbances are identified and controlled within rt mes.

Simplify your shop floor with rfid technology use the latest technology to make routine tasks like clocking in and out uncomplicated.

First in the industry to integrate rfid sdt is gpro s flagship solution that tracks hundreds of semi finished apparel pieces from parts sub part.

Mapping the shop floor to it enabled business processes dissertation.

Global shop solutions rfid technology saves time and improves building security by consolidating these three processes into one.

Gone are the days of fumbling to get a barcoded badge under the scanner removing a work glove to access your fingerprint or pressing your fingerprint to the pad only to have it not read correctly.