Grp ltd established in 1974 is among the most recognised manufacturer of reclaimed rubber from used tyres upscaled polyamide from nylon waste and engineered products die cut from end of life tyres.

Reclaim rubber uses.

Ltd the reliable and prestigious name in the field of reclaimed rubber manufacturing which is situated in rajkot gujarat india the industrial hub of india manufactures butyl reclaim rubber and natural reclaim rubber from the scrap of natural rubber tubes butyl rubber tubes and tyre reclaim rubber from whole tyre scrap accordingly.

Recycled rubber strips and sheets old rubber tires made anew.

Consistent quality provides tremendous opportunities for tire and non tire applications.

Tire reclaim used in a typical tire sidewall compound would make up over 50 of the total rubber.

Tire recycling or rubber recycling is the process of recycling waste tires that are no longer suitable for use on vehicles due to wear or irreparable damage.

For instance many civil engineering companies use rubber tubes during their method of construction.

The company operates 5 business verticals reclaim rubber industrial polymers custom die forms retreading rubber composite with 8.

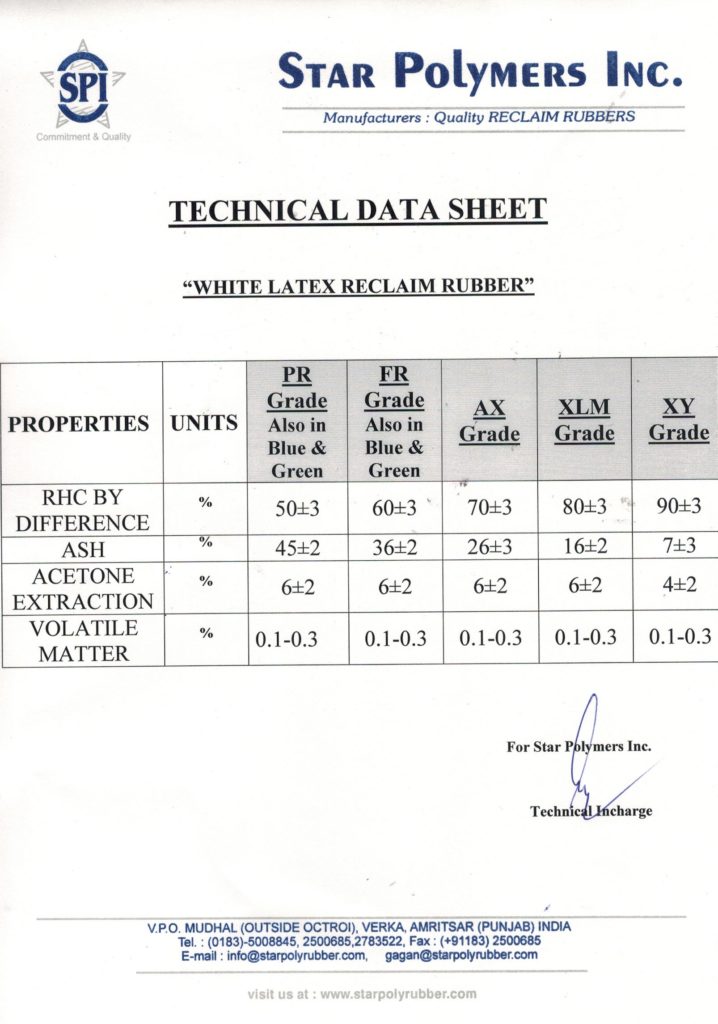

The grades are superfine fine medium coarse depends on the grain size of the reclaim rubber.

Everyone from scientists engineers to urban planners is searching for the ways in.

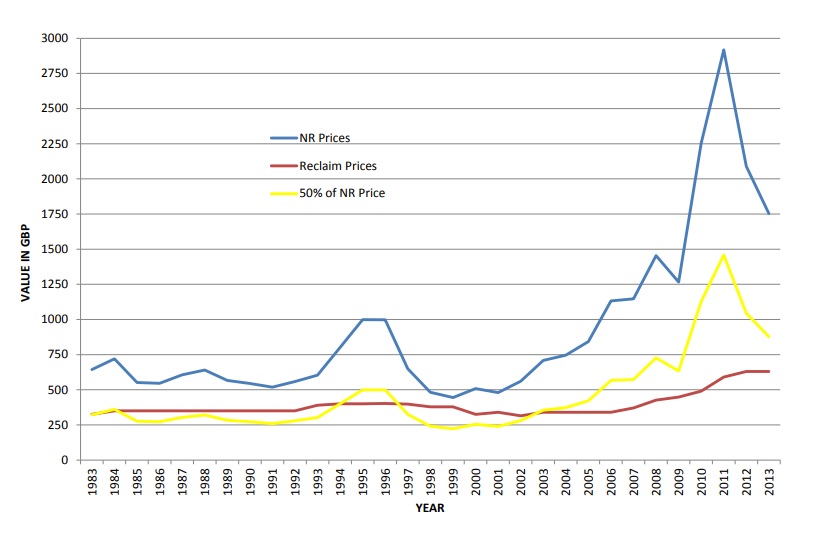

Reclaim rubber is significantly less expensive than the natural and synthetic rubber alternatives.

We live in an era where there is a growing concern for the depletion of the world s natural resources and accumulation of greenhouse gases.

Similarly natural rubber tubes reclaimed for their uses.

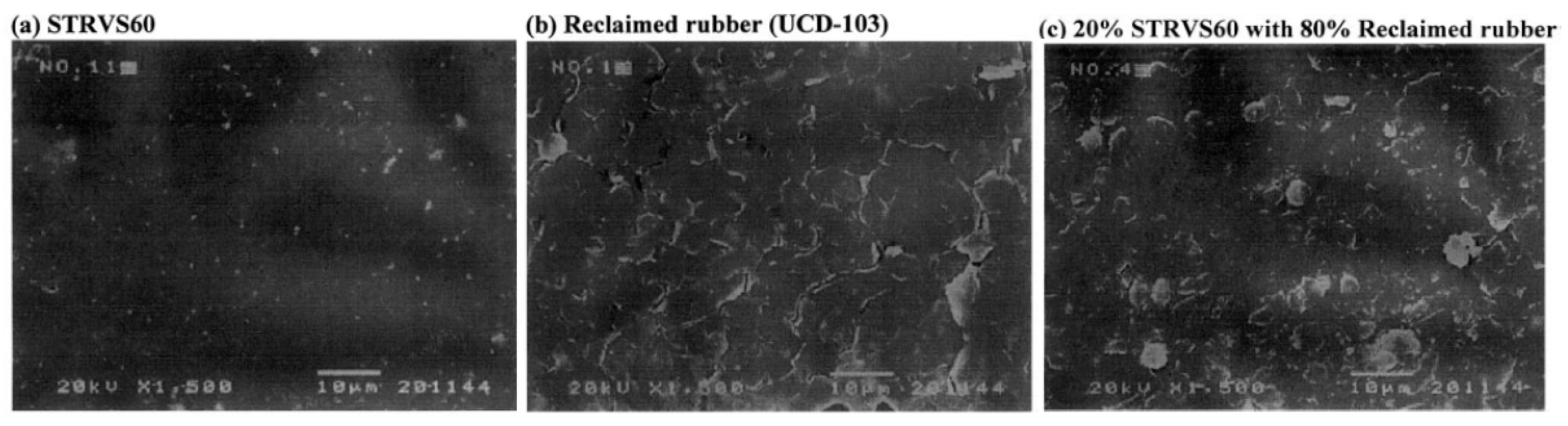

The reclaim rubber was inherently a better product since it retained a higher of original properties and still gave much improved processing properties.

Bejing china rubber industry association has released self disciplinary standards for environmental protective reclaimed rubber used in tires according to a cria.

Whole tyre reclaim this is manufactured from the used tyres and can be used for moulded extruded products.

This provides cost savings to customers without compromising the quality.

Whereas rubber is also used as fuel majorly by.

Nowadays many manufacturers have started buying the rubber scrap and with the help of the thermo chemical process they reclaim rubber.

The standards made in reference to european union regulations aim to eliminate high polluting processes and the use of hazardous materials such as coal tar.

These tires are a challenging source of waste due to the large volume produced the durability of the tires and the components in the tire that are ecologically problematic.