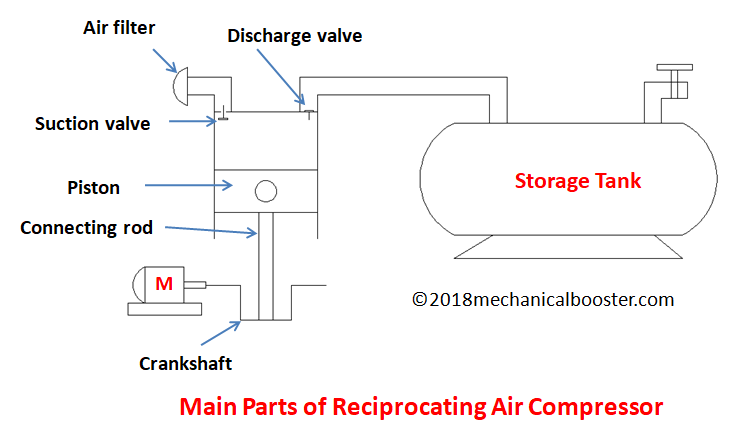

In reciprocating air compressor as the piston moves towards the bdc the air is sucked into the cylinder from the atmosphere and when it moves towards the tdc the compression of the air starts and keeps on going and pressure increases.

Reciprocating air compressor working principle pdf.

The compression process requires work input.

But according to stages the building of discharge pressure is different in each compressor.

Read here to know about various types of air compressors used and get a clear inside view of each type of compressor with the attached pictures.

Analysis of cycle.

Reciprocating air compressor has also classified according to its stages.

Types of rotary compressor.

A hand operated tire pump is an example of a simple air compressor.

Air from atmosphere enters into the compressor it is compressed to a high pressure.

An air compressor takes air at atmospheric pressure and raises it to a higher pressure.

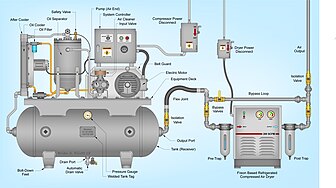

Generally an electric motor is used as prime mover.

4 3 working principle of a compressor.

Air enters the pump s cylinder as the plunger is raised.

Energy used by an industrial air compressor is converted into heat.

Positive displacement and roto dynamic compressors.

Fig 4 1 air compressor a line diagram of a compressor unit is shown in fig 4 1.

Net potential is 40 to 84 recovery.

So classification will help you better understand the working of the reciprocating air compressor.

The area under the.

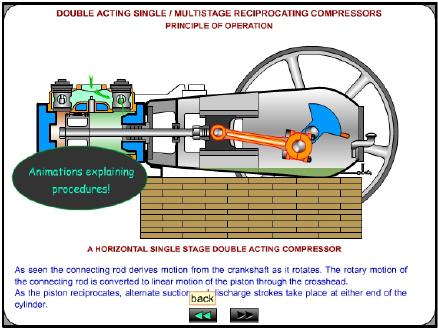

The compressor working principle involves the reciprocating action of a piston inside a cylinder which compresses air gas inside the cylinder.

Screw compressors vane type compressors lobe.

The principle of operation is same in each type.

Positive displacement compressors cab be further divided into reciprocating and rotary compressors.

Reciprocating compressor working principle animation video reciprocating compressor belong to the category of positive displacement compressors.

Indicated work cycle area a b c d area 1 2 3 4 1 area under 1 2 area under 2 3 area under 4 1.

Rotary compressors and types working principle engineering explained rotary screw compressor working working principle air sucked in at one end and gets trapped between the rotors and get pushed to other side of the rotors the air is pushed by the rotors that are rotating in opposite direction and compression is done when it gets trapped in.

They are the reciprocating compressor which has piston working only in one direction the other end of the piston is often free or open from which no work is performed there is only one side compression or the upper part of the piston is used to compress the air the bottom part is open to crankcase and is not utilized for the compression of air.

Represents the net or indicated work done on the air per cycle.

The operator then pushes down on t.

In many cases a properly designed heat recovery unit can recover anywhere from 50 to 90 percent of this available thermal energy and put it to useful work heating air or water.

C b d.